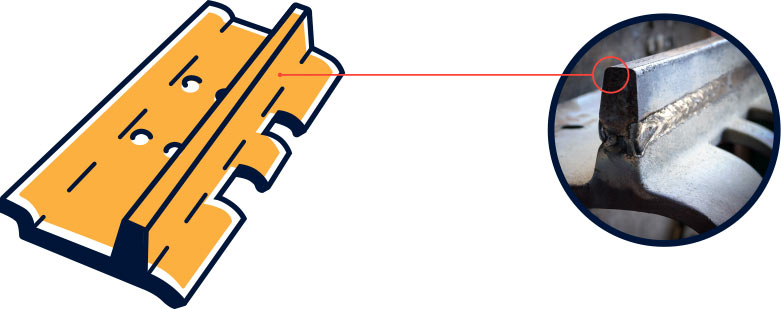

Grouser Bar Kanggo Bulldozer lan Excavator

Bar grouser minangka komponen logam sing biasane ditemokake ing mesin abot, kayata buldoser lan loader trek. Iki dipasang ing sepatu trek lan mbantu nambah daya tarik lan genggeman kanthi nresep ing lemah. Bar Grouser penting kanggo nambah kinerja mesin ing terrain sing tantangan, kayata lemah sing longgar utawa lereng sing curam. Padha teka ing macem-macem wangun lan ukuran kanggo cocog aplikasi beda lan bisa diganti nalika worn metu kanggo njaga fungsi optimal.

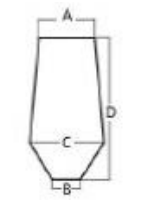

| BAGIAN | A mm | B mm | C mm | D mm | Dawane (mm) | W (kg) |

| 225 | 15 | 8 | 19 | 18 | 225 | 0.51 |

| 335 | 20 | 10 | 24 | 21 | 335 | 1.13 |

| 594 | 28.5 | 12.5 | 36.5 | 64 | 594 | 9.4 |

| 610 | 7 | 5 | 22 | 40 | 610 | 2.8 |

| 910HT-558 | 28.575 | 12.7 | 38.1 | 63.5 | 558 | 9.04 |

| 911HT-558 | 26.987 | 12.7 | 41.275 | 82.55 | 558 | 11.55 |

| 911HT-610 | 26.987 | 12.7 | 41.275 | 82.55 | 610 | 12.7 |

| ACORK3 | 10.17 | 6.35 | 19.05 | 31.75 | 76.2 | 0.28 |

| D10 | 27 | 14 | 36 | 68 | 610 | 10 |

| D10-558 | 28.58 | 14.29 | 38.1 | 66.675 | 558 | 9.5 |

| D10-610 | 28.58 | 14.29 | 38.1 | 66.675 | 610 | 10.4 |

| D11 | 27 | 14 | 41 | 82.5 | 711 | 15.2 |

| D12-610 | 34.925 | 12.7 | 44.45 | 76.2 | 610 | 13.8 |

| D7-508 | 16 | 7.94 | 19 | 35.5 | 508 | 2.5 |

| D8-508 | 19.05 | 9.525 | 25.4 | 50.8 | 508 | 4.4 |

| D9-558 | 24.1 | 7.94 | 33 | 50.8 | 558 | 6.1 |

| D9-610 | 24.1 | 7.94 | 33 | 50.8 | 610 | 6.6 |

| ECORK4 | 10.17 | 7.52 | 19.41 | 38.2 | 76.2 | 0.34 |

| KCORK-4.25" | 14.3 | 9.5 | 19.1 | 31.75 | 108 | 0.44 |

| SCORK-4.25" | 25.4 | 7.9 | 28.6 | 50.8 | 108 | 1.1 |

| TCORK-4.25" | 25.4 | 6.4 | 28.6 | 38.1 | 108 | 0.84 |

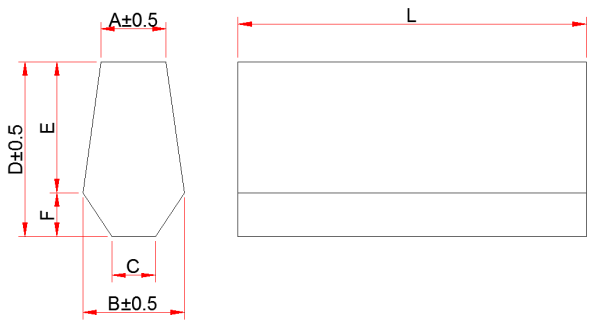

Materi sing beda kanggo referensi

Bahan: 65Mn Kekerasan: HB300~HB320 Panjang bisa disesuaikan, maksimal 6000mm

| Nomer bagean | A | B | C | D | E | F | L | W (KG) |

| BAR-C-3 | 14.3 | 22.2 | 9.53 | 38.11 | 28.58 | 9.53 | 76.2 | 0.405 |

| BAR-K-4 | 14.3 | 19.1 | 9.53 | 31.76 | 34.93 | 9.53 | 101.6 | 0.4075 |

| BAR-L-3 | 11.1 | 15.9 | 6.35 | 25.4 | 19.05 | 6.35 | 76.2 | 0.1974 |

| BAR-E-3 | 9.5 | 19.1 | 7.94 | 38.1 | 31.75 | 6.35 | 76.2 | 0.325 |

| BAR-A-3 | 9.5 | 15.9 | 6.35 | 34.93 | 28.58 | 6.35 | 76.2 | 0.261 |

Bahan: 40Cr Kekerasan: HB500 Casting lan perawatan panas dibutuhake.

| Nomer bagean | A | B | C | D | E | F | L | W (KG) |

| ECORK 3 | 9.5 | 19.1 | 7.94 | 38.15 | 31.8 | 6.35 | 76.2 | 0.326 |

| GCORK 4 | 14.3 | 25.4 | 9.53 | 44.46 | 34.93 | 9.53 | 101.6 | 0.69 |

| JCORK 4 | 19.1 | 28.6 | 9.53 | 60.3 | 49.2 | 11.1 | 101.6 | 1.11 |

| AKAR 3 | 9.5 | 15.9 | 6.35 | 31.7 | 25.4 | 6.35 | 76.2 | 0.237 |

| WCORK 2.5 | 8 | 14.3 | 6.5 | 19.1 | 13.92 | 5.18 | 63.5 | 0.105 |

| KORK 4 | 14.3 | 19.1 | 9.53 | 31.76 | 22.23 | 9.53 | 101.6 | 0.405 |

| HCORK 4 | 15.9 | 25.4 | 9.53 | 52.39 | 41.28 | 11.11 | 101.6 | 0.835 |

| KORK 3 | 14.3 | 22.2 | 9.52 | 38.1 | 28.58 | 9.52 | 76.2 | 0.405 |

Bahan: 42CrMoNi Kekerasan: HB500-550 Casting lan perawatan panas dibutuhake.

| Nomer bagean | A | B | C | D | E | F | L | W (KG) |

| D9-610 | 24.1 | 33 | 7.94 | 50.8 | 41.28 | 9.53 | 610 | 6.6 |

| D10-610 | 28.58 | 38.1 | 14.29 | 66.68 | 57.15 | 9.53 | 610 | 10.4 |

- Wangun endi sing paling cocog karo pola nganggo sampeyan?

STRAIGHT BAR

- Pola nganggo malah kabeh liwat

- Sepatu dipotong kanggo permukaan sing rata

- Bisa uga karo welders otomatis

BAR NGAPUSI

- Pola nyandhang bunder kanthi pinggiran sing rusak banget

- Ngilangi kabutuhan trimming

- Ujung bar dipotong kanthi sudut 45 derajat kanggo resistensi balik sing kurang lan dhukungan tambahan

- Ujung bar kecanthol dirancang kanggo pas karo sepatu trek kanthi nyandhang abot ing pinggir

- Becik kanggo sepatu trek sing dilas ing lapangan

BAR MUNGKUNG

- Pola nganggo rada bunder

- Ngilangi kabutuhan trimming

- Bentuk bar sing mlengkung nyuda jumlah las sing dibutuhake

- Becik kanggo sepatu trek sing dilas ing lapangan

BAR BEVELED

- Pola nganggo malah kabeh liwat

- Sepatu dipotong kanggo permukaan sing rata

- Ujung bar dipotong kanthi sudut 45 derajat kanggo resistensi balik sing kurang lan dhukungan tambahan

- Bisa uga karo welders otomatis