Segmen Forging kanggo Shantui Komatsu CAT

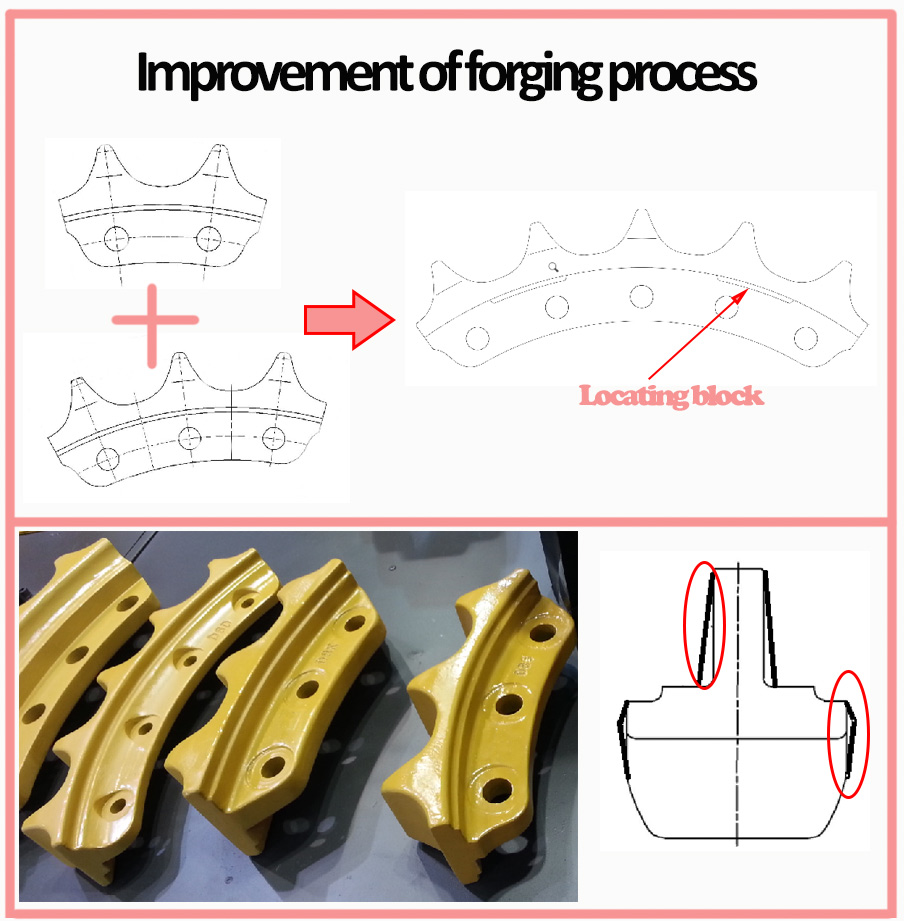

Peningkatan proses penempaan

Ngganti saka loro utawa telu untu dadi limang untu nyuda kedadeyan pemblokiran waos loosening. Ngganti bunder posisi menyang blok posisi nyuda kesalahan mesin lan gangguan ing antarane bunder posisi lan permukaan instalasi sing disebabake deformasi perawatan panas.

Amarga proses forging, sisih lan flange lumahing sakaperangan ing proses forging mujur kudu makaryakke amba konsep tartamtu, lan lumahing machined produk semi-rampung palsu kudu diproses.

Model Kita Bisa Nyedhiyakake

| SEGMEN | ||||||||

| Model | OEM | Pitch | waos | Hols | Bukaan (mm) | Bobot | Merk | OEM liyane (BERCO) |

| DH08 | 111H-18-00001 | 154 | 3 | 3 | 17.5 | 4.1 | shantui | |

| 111H-18-00002 | 4 | 4 | 17.5 | 5.5 | shantui | |||

| SD 13 | 10Y-18-00043 | 190 | 5 | 5 | 19.3 | 10.75 | shantui | |

| DH36 | 1175-18-00009 | 228.6 | 6 | 6 | 26.5 | shantui | ||

| 1175-18-00035 | 5 | 5 | 26.5 | |||||

| SD16, D65, D60, D85ESS-2 | 16Y-18-00014H | 203.2 | 3 | 3 | 23.5 | 8.5 | shantui/komatsu | 14X-27-15112/1,141-27-32410,144-27-51150,615-4149,KM2111,KM162 |

| (16Y-18-00049) | ||||||||

| SD 22, D85 | 154-27-12273A | 216 | 5 | 5 | 23.5 | 15 | shantui/komatsu | 155-27-00151,615-4150,KM224 |

| SD32, D155 | 175-27-22325A | 228.6 | 3 | 3 | 26.5 | 12 | shantui/komatsu | 175-27-22325/4 17A-27-11630,KM193,17A-27-41630 |

| SD52, D375 | 185-18-00001 | 280 | 5 | 5 | 28.5 | 33 | shantui/komatsu | 195-27-33110/1,KM1285 |

| SD90, D475 | 1189-18-00001/ | 317.5 | 5 | 5 | 31.5 | 43 | shantui/komatsu | |

| 198-27-42260 | ||||||||

| D50, D41, D58, D53 | 131-27-61710 | 175 | 3 | 3 | 19.5 | 6 | komatsu | 131-27-61710, 131-27-42220, KM788 |

| D5B | 5S0836 | 175 | 3 | 3 | 18 | 5 | CAT | 6Y5244, CR4408.7P2636 |

| D6D/C/G | 6T4179/6T4179/6P9102 | 202.8 | 5 | 4 | 17.8/20.8 | 11.57 | CAT | 6Y5012,5S0050,7P2706,CR3330,CR3329,8P5837,8E4365/CR5476,117-1616 |

| D6H/R | 6Y2931/1026677 | 202.8 | 5 | 5 | 17.8 | 11.5 | CAT | 7G7212,8E9041,7T1697,CR5515,173-0946 |

| D7G/E/F | 8E4675/8E4675/8E4675 | 216 | 5 | 4 | 20.8 | 14.7 | CAT | 5S0052,3P1039,8P8174,CR3148 |

| D8N/R.D7H/R | 7T9773/6Y2354, | 215.9 | 5 | 7 | 20.8 | 16.4 | CAT | 6Y3928, CR5050, 9W0074 |

| 6Y2354/7T9773 | ||||||||

| D8N/R.D7H/R | 314-5462 | 215.9 | 5 | 5 | 20.8 | 16.4 | CAT | CR7160 |

| D8K.D8H | 6T6782/6T6782 | 228.6 | 3 | 3 | 24.5 | 12 | CAT | 2P9510,5S0054,CR3144 |

| D6N.D6M | 6I8077/6I8077 | 190 | 5 | 5 | 18.5 | 9 | CAT | 6I8077/8,CR5875 |

| D9N | 7T1247 | 240 | 5 | 6 | 24.6 | 23.98 | CAT | CR4686 |

| D10N | 6T9537 | 260.35 | 5 | 6 | 27.61 | 26.7 | CAT | CR5047 |

| 832 | 632-7793 | 228.6 | 3 | 5 | 26.5 | 11.63 | CAT | |

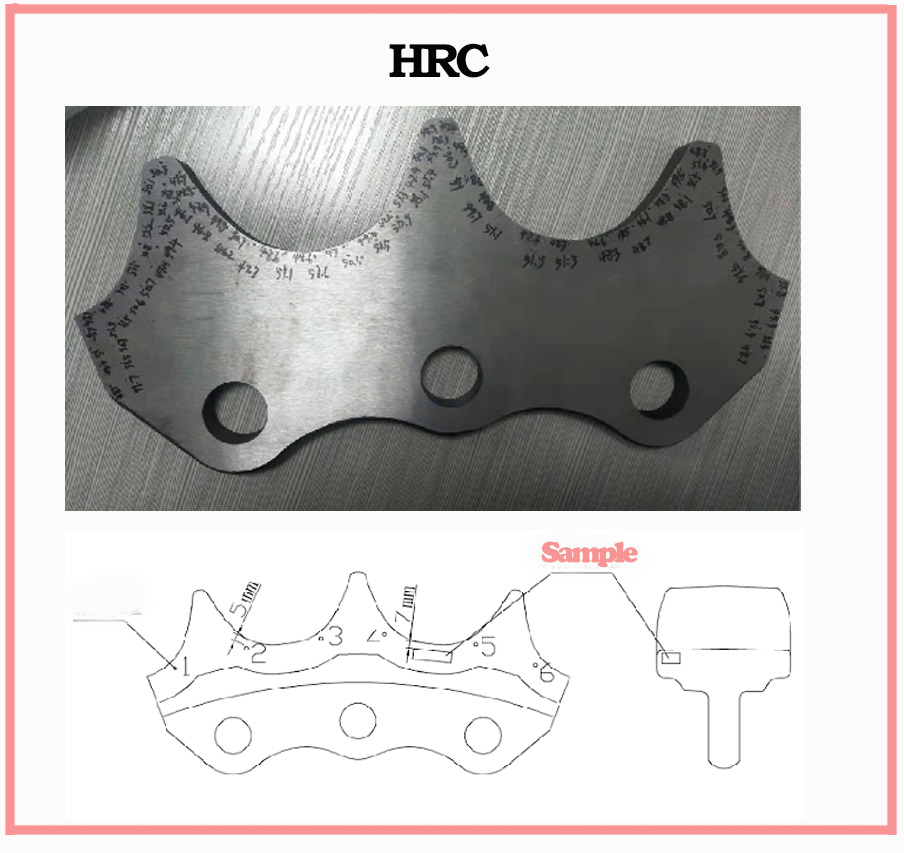

HRC

Amarga proses forging, sisih lan flange lumahing bagean ing proses forging mujur kudu makaryakke amba konsep tartamtu, lan lumahing machined produk semi-rampung palsu kudu diproses.

Packing