Hydraulic Breaker Chisel Excavator Blunt Wedge Diamond Point

Deskripsi Pahat

Kanggo pemasok bahan mentah sing disenengi, bahan 40Cr lan 42CrMo dianggep minangka pilihan sing berkualitas.Kaloro bahan kasebut nduweni sifat mekanik lan daya tahan sing apik lan cocok kanggo sawetara aplikasi sing mbutuhake kekuatan dhuwur lan resistensi nyandhang dhuwur.Ing babagan perawatan panas, peralatan perawatan panas sing luwih apik bisa nggunakake proses lan peralatan canggih kanggo njamin kualitas lan kinerja bahan.Liwat limang pangolahan perawatan panas, kalebu rong tahap tempering, ambane lapisan hardened bisa èfèktif tambah lan atose lan kekiatan materi bisa apik.Kanthi cara iki, umur layanan produk bisa ditambah 30% nganti 80%.Dandan iki bisa nggawe bahan 40Cr lan 42CrMo luwih awet lan stabil.Nalika milih panyedhiya bahan mentah, priksa manawa bahan kasebut berkualitas tinggi lan cocog karo standar, dene proses perawatan panas sing luwih apik bisa nambah kinerja materi.

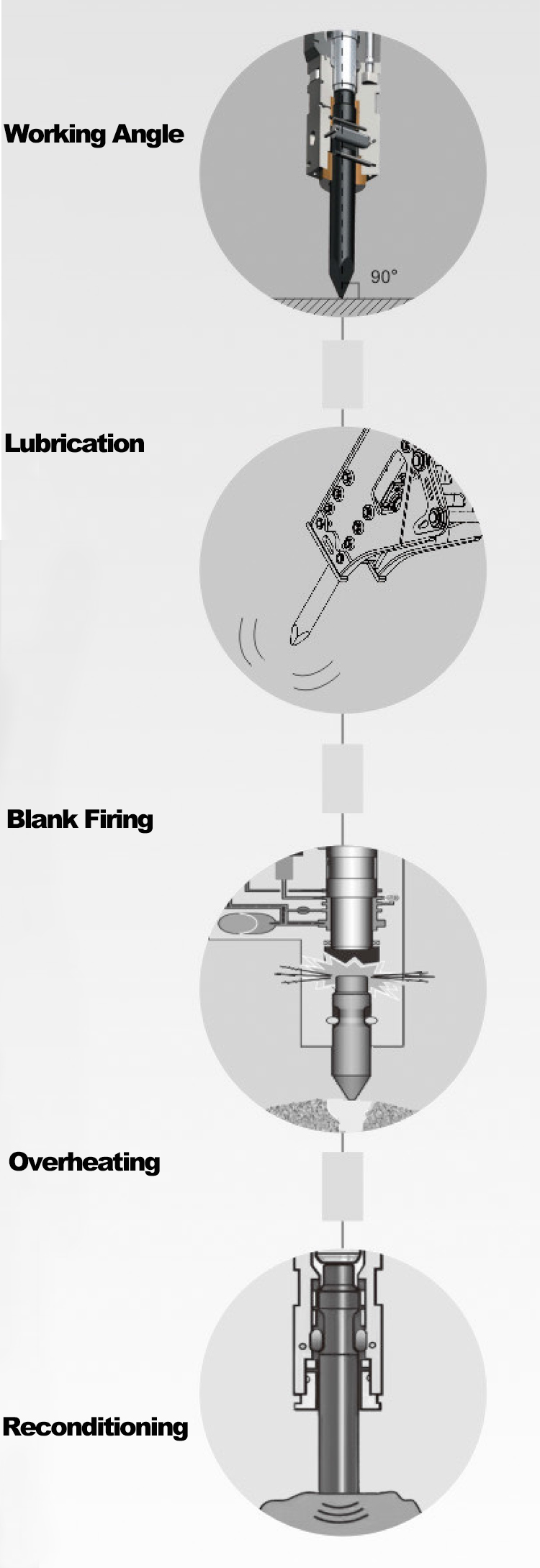

Sudut Kerja

operasi serangan vertikal Iku bener kanggo nggawe rod lan lumahing apa jejeg amba 90 °, supaya njamin urip layanan saka rod.Yen sudut ora bener, tekanan sing luwih dhuwur bakal berkembang ing antarane rod lan bushing, nyebabake nyandhang ing permukaan kontak lan potensial karusakan ing rod utawa bushing.Bushing worn bisa nimbulaké rod miring lan karusakan sakteruse kanggo piston.

Lubrication

lubricating Ajeg nggunakake kualitas dhuwur-suhu lan dhuwur-tekanan lubricating lenga kanggo lubricate lumahing kontak antarane rod lan bushing.Cara kerja sing salah, kayata striking ing sudhut, prying obyek utawa mlengkung banget, bisa gawé tekanan dhuwur ing lumahing kontak.Pelumas nyedhiyakake proteksi sing luwih apik lan ngluwihi umur layanan.

Blank Firing

Pukulan Kering Serangan garing bisa kedadeyan nalika rod ora nyedhaki permukaan kerja, nyelip ing obyek sing rusak, utawa obyek kasebut alus banget utawa tipis.Batang kasebut bisa nyerang pin penahan, lan kekuwatan impact bisa nyebabake nyandhang utawa rusak pin.Disaranake kanggo mriksa kutub kanthi rutin, luwih becik saben 30-50 jam, kanggo mriksa karusakan lan ndandani cacat.Uga, priksa bushing kanggo nyandhang utawa rusak lan ngganti utawa ndandani yen perlu.

Overheating

Suhu dhuwur banget lan kedadean jamur katon Aja nggebug siji posisi terus-terusan luwih saka 10-15 detik.Nganti suwene tanpa ngrusak obyek kasebut bakal nyegah panas supaya ora ilang ing sirah klub.Nalika kakehan panas digawe munggah, teken bisa decarb lan dadi alus, nyebabake jamur utawa clumps.Akibaté, urip layanan rod bakal shortened utawa bisa uga kudu scrapped.

Rekondisi

Pangopènan biasa Umumé, rod ora mbutuhake ndandani.Nanging, deformasi sirah nyebabake tekanan dhuwur ing kabeh permukaan kontak antarane rod lan pemutus.Dianjurake kanggo ndandani kanthi panggilingan utawa ngowahi.Welding utawa nglereni geni ora dianjurake amarga panas kui bisa nimbulaké owah-owahan struktural ing materi lan akselerasi nyandhang.

Model pahat kita bisa nyedhiyakake

| Pahat Excavator Kab | |||||||

| Bahan : 42cm Kab | |||||||

| Model | Dia | Lengt | Bobot | Model | Dia | Lengt | Bobot |

| SOOSAN | FURUKAWA | ||||||

| SB43 | 75 | 740 | 23 | HB100 | 55 | 500 | 9 |

| SB50 | 100 | 1050 | 58 | HB200 | 70 | 510 | 13 |

| SB60 | 120 | 1050 | 91 | HB700 | 104 | 940 | 49 |

| SB70 | 135 | 1200 | 117 | HB1G | 36 | 400 | 3 |

| SB80 | 140 | 1200 | 130 | HB2G | 45 | 460 | 4 |

| SB120 | 155 | 1450 | 193 | HB3G | 60 | 560 | 11 |

| SB121 | 155 | 1450 | 193 | HB5G | 75 | 650 | 20 |

| SB130 | 165 | 1500 | 227 | HB10G | 105 | 1000 | 65 |

| SB130-3 | 155 | 1500 | 185 | HB15G | 120 | 1000 | 80 |

| SB150 | 175 | 1600 | 272 | HB30G | 150 | 1300 | |

| SB160 | 175 | 1600 | 272 | F-1 | 36 | 400 | 3 |

| SH200 | 70 | 600 | 16 | F-2 | 45 | 480 | 5 |

| SH400 | 95 | 840 | 40 | F-3 | 52 | 520 | 8 |

| SH700 | 105 | 930 | 55 | F-4 | 60 | 540 | 11 |

| SH18G | 120 | 1110 | 85 | F-5 | 68 | 610 | 16 |

| SH20G | 135 | 1200 | 120 | F-6 | 75 | 720 | 23 |

| SH30G | 150 | 1300 | 157 | F-9 | 90 | 800 | 32 |

| SH35G | 140 | 1300 | 137 | F-12 | 105 | 1000 | 66 |

| SH40G | 160 | 1400 | 192 | F-19 | 120 | 1100 | 86 |

| SH50G | 180 | 1515 | 263 | F-22 | 135 | 1200 | 117 |

| SB30 | 53 | 580 | 9 | F-35 | 150 | 1400 | 169 |

| KRUPP | INDECO | ||||||

| HM130/131/135/140V | 65 | 780 | 18 | MES180/181/200 | 48 | 550 | 6 |

| HM300/301/305 | 80 | 900 | 30 | MES300/301/350/351 | 55 | 600 | 10 |

| HM170/185/190V | 75 | 800 | 25 | MES451/521/550/HB5 | 65 | 650 | 14 |

| HM550/560CS/V | 100 | 1000 | 55 | MES601/621/650 | 80 | 650 | 22 |

| HM700/720CS/V | 115 | 1080 | 82 | MES1200-HB12 | 90 | 800 | 34 |

| HM900/901/902 | 135 | 1150 | 115 | MES1500/HB19 | 110 | 900 | 55 |

| HM950/960/SC/V | 135 | 1080 | 110 | MES1750/1800 | 114 | 1000 | 72 |

| HM1300/1500CS/V | 150 | 1200 | 151 | MES121/150 | 45 | 480 | 5 |

| HM1800/2000CS/V | 160 | 1400 | 220 | MES2000/HB27 | 120 | 1000 | 78 |

| HM2200/2500CS/V | 180 | MES2500 | 130 | 1100 | 101 | ||

| HM45 | 42 | 470 | 6 | MES3000 | 140 | 1200 | 130 |

| HM50/55 | 45 | 480 | 7 | MES3500 | 145 | 1300 | 155 |

| HM60/75 | 55 | 590 | 10 | MES4000 | 150 | 1300 | 160 |

| HM85/90 | 62 | 600 | 11 | MES5000 | 160 | 1350 | 190 |

| HM100/101 | 65 | 700 | 18 | MKB | |||

| HM200 | 80 | 785 | 27 | MKB1300N | 135 | 1150 | 116 |

| HM400/401 | 80 | 800 | 27 | MKB1400 | 135 | 1150 | 116 |

| HM600/601 | 100 | 1000 | 55 | MKB2000 | 150 | 1250 | 156 |

| HM800 | 135 | 1150 | 115 | MKB2000N | 149 | 1250 | 154 |

| HM1200 | 120 | 1250 | 155 | MKB2500 | 160 | 1350 | 185 |

| GUANGLIN | MKB3000 | 165 | 1500 | 227 | |||

| SG1800 | 135 | 1200 | 120 | MKB4000N | 180 | ||

| SG2100 | 138 | 1250 | 125 | MKB100 | 45 | 450 | 5 |

| Model | Dia | Lengt | Bobot | Model | Dia | Lengt | Bobot |

| GUANGLIN | MKB | ||||||

| SG2500 | 145 | 1300 | 151 | MKB150 | 55 | 600 | 10 |

| SG2800 | 155 | 1450 | 190 | MKB200 | 65 | 600 | 14 |

| SG3200/3300 | 158 | 1500 | 200 | MKB300N | 70 | 750 | 20 |

| SG5000 | 180 | 1600 | 280 | MKB400 | 80 | 600 | 21 |

| SG200 | 45 | 500 | 5 | MKB500 | 80 | 600 | 21 |

| SG300 | 57 | 600 | 10 | MKB800 | 100 | 1000 | 55 |

| SG350 | 68 | 700 | 17 | MKB900N | 100 | 1000 | 55 |

| SG400 | 75 | 690 | 20 | MKB1200 | 115 | 1150 | 84 |

| MONTABERT | DAENO | ||||||

| BRH75/76/90/91 | 60 | 550 | 8 | DMB03 | 68 | 600 | 16 |

| BRP85/100 | 62 | 620 | 12 | DMB04 | 95 | 900 | 43 |

| BRP130/150 | 75 | 740 | 21 | DMB06 | 105 | 930 | 55 |

| BRV32 | 122 | 1100 | 90 | DMB4000 | 150 | 1450 | 181 |

| BRV43 | 150 | 1300 | 160 | DMB5000 | 165 | 1600 | 249 |

| BRV45 | 150 | 1300 | 160 | S150 | 57 | 600 | 10 |

| BRV52 | 162 | 1350 | 192 | S500 | 69 | 680 | 18 |

| BRV53 | 170 | 1400 | 230 | S900 | 85 | 830 | 33 |

| BRV55 | 170 | 1500 | 245 | S1300 | 105 | 926 | 56 |

| BRV1600 | 140 | S1800 | 120 | 1000 | 80 | ||

| BRH40 | 45 | 500 | 6 | S2200-1 | 130 | 1200 | 112 |

| BRH125 | 80 | 700 | 21 | S2000-2 | 135 | 1200 | 121 |

| BRH250/270 | 95 | 850 | 40 | S2500 | 140 | 1200 | 130 |

| BRH501/570 | 114 | 1000 | 76 | S3000/3600/4500 | 150 | 1350 | 168 |